We enable Digital Product Passports for plastics

R-Cycle provides an open, globally applicable and accepted traceability standard for plastic products. Driven by a cross-industry community, we create a data infrastructure for the operation of Digital Product Passports.

R-Cycle - explained in 60 seconds

How to get started with your first Digital Product Passport and fulfill various information requirements for your packaging quickly and easily.

Let's network: R-Cycle on LinkedIn

On our LinkedIn profile, we inform you about all developments around R-Cycle and

keep you up to date with the latest trends on Digital Product Passports as part of an efficient circular economy.

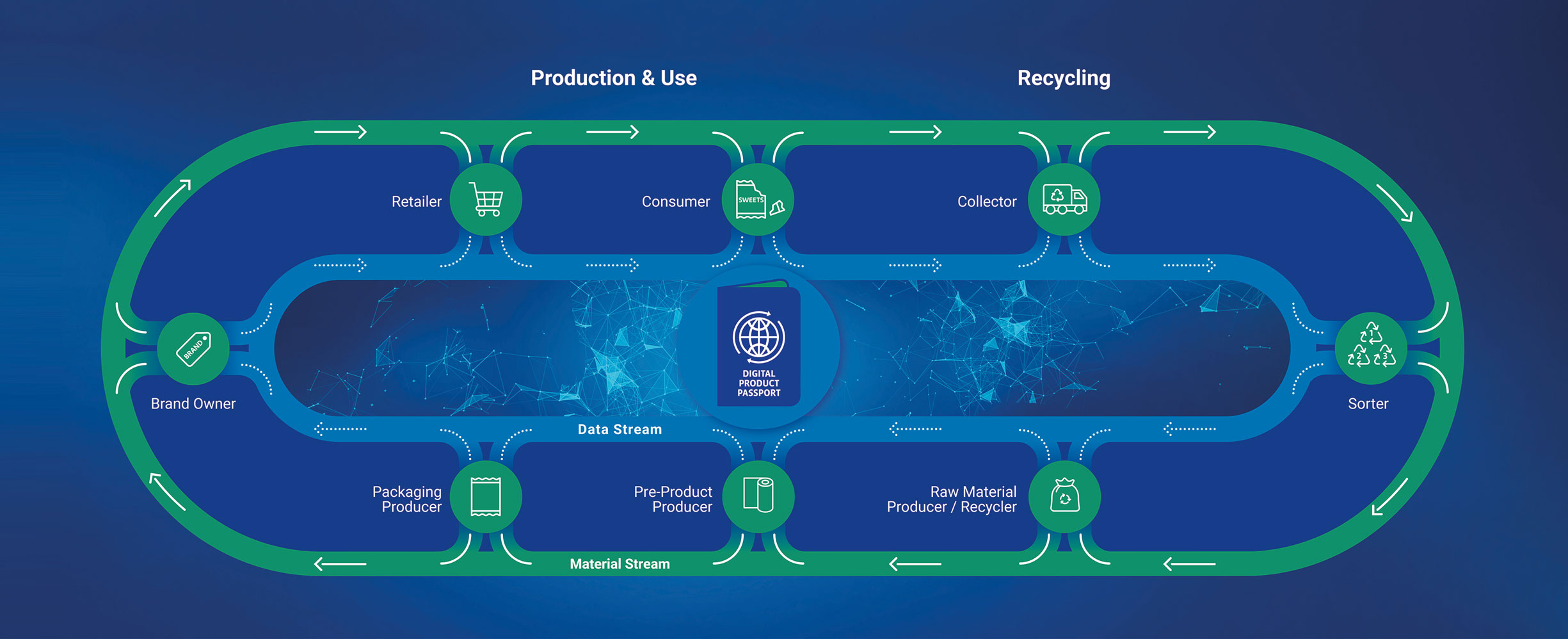

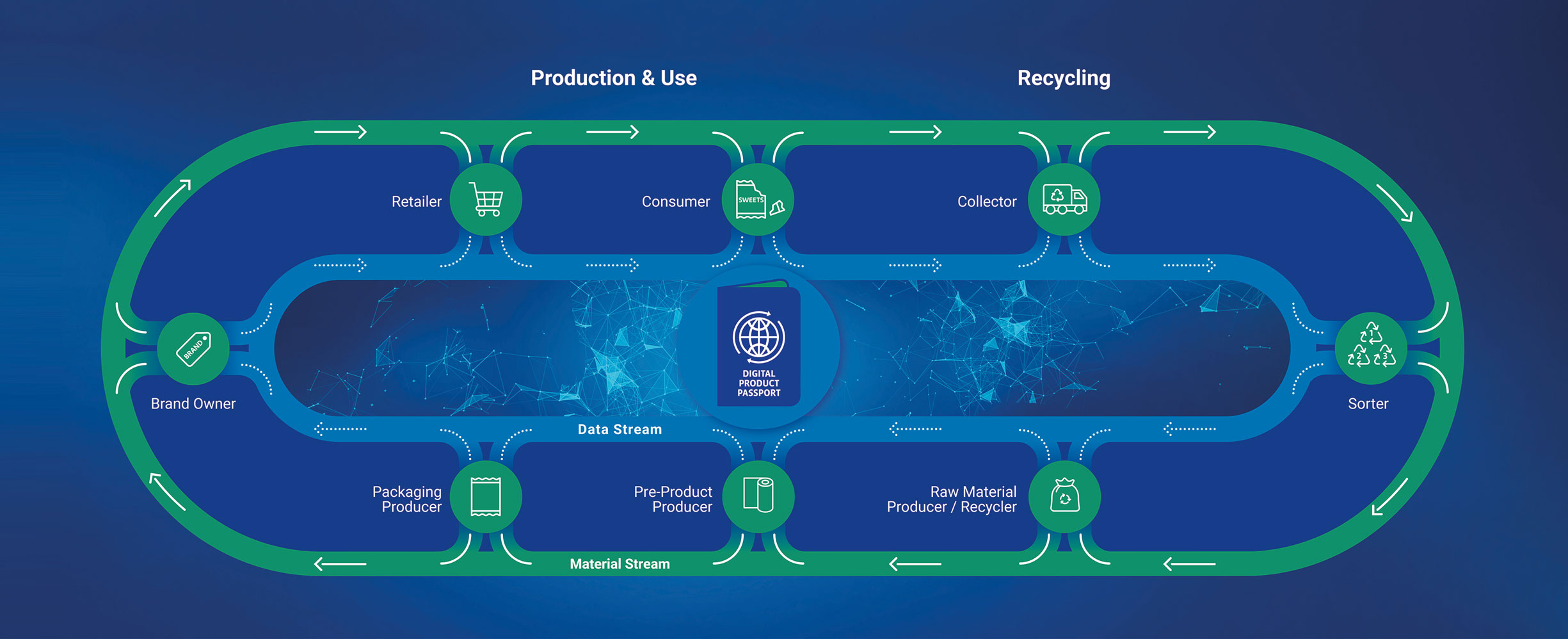

Data-based circular economy

By automatically capturing all relevant properties of plastics along the value chain, R-Cycle enables data-based management of material streams for more efficient manufacturing, improved waste sorting and higher-quality recyclates. R-Cycle thus paves the way for plastic products into a functioning circular economy, for which we have already received several awards.

Who is behind R-Cycle?

Leading global companies and organizations along the entire plastics value chain rely on R-Cycle as a solution for Digital Product Passports. Together with our partners in various projects and applications, and members of the R-Cycle Community, we are driving the establishment of R-Cycle based on international GS1 standards.

R-Cycle in practice

R-Cycle partner Brückner Maschinenbau shows a crisp bag production for the circular economy:

Why R-Cycle?

Digital Product Passports create the basis for data-based material streams. From production and further processing to use and disposal, this data can be read and supplemented, for example, to show recyclate proportions, optimize production processes or identify recyclable products in the waste stream.

With R-Cycle, you get a ready-to-use solution to use Digital Product Passports for your specific application and create added value for yourself and your customers.

The Digital Product Passport

The Digital Product Passport is a (digital) system for recording, aggregating and providing data on a product along its life cycle. It can be retrieved on intermediate and end products via suitable marking (e.g. digital watermarks or QR codes).

The data infrastructure behind R-Cycle is based on GS1 standards - the leading global network for cross-industry process development. GS1 standards are used for more than six billion scanned barcodes every day. The underlying technology - the so-called EPCIS standard - is already being used successfully in various industries worldwide.

What is the R-Cycle Community?

R-Cycle was developed to market maturity by various technology companies and organizations along the entire life cycle of plastic products. As a cross-industry community, we establish an open and globally applicable traceability standard that ensures complete documentation.

As a community member, you gain exclusive access to the R-Cycle network, strengthening your business relationships. With the support of experienced partners, you can start collaborations, gain insights into ongoing projects and find applications for your business.

Who can use R-Cycle?

R-Cycle can be networked with any production line, from film, blow molding or injection molding machines to processing, printing and filling machines, as well as waste sorting and recycling systems. In addition, Digital Product Passports can be used to provide information on end products to retailers or consumers. We have already proven this together with various partners in numerous projects.

News from the R-Cycle world

You have questions? We have answers!

Unlike metal or glass, plastic packaging is in most cases not homogeneous, but consists of numerous different components, for example different plastics, additives, printing inks or adhesives. This makes sorting in the recycling process more difficult, because recyclable plastics cannot be reliably distinguished from non-recyclable plastics. It is therefore hardly possible at present to classify plastics into pure fractions.

Only low-grade recyclates can be obtained from today's fractions, which are only suitable for a very narrow range of applications (for example, for the production of trash cans or park benches). Low-grade recyclate cannot be used for high-value applications, such as food packaging. A large proportion of plastic waste is therefore only thermally recycled (incinerated). In order to be able to process recyclate into food packaging, for example, it must be ensured that the recyclate is not contaminated with hazardous substances. This absolutely requires traceability of the origin of the recyclate.

In contrast to other initiatives, R-Cycle focuses on the collection and aggregation of packaging data along the life cycle in order to make it available to a wide range of applications and stakeholders.

The results of other initiatives, such as those focusing on marking technologies and its detection, are the prerequisite for realizing a true circular economy in interaction.

Accordingly, other initiatives can build on the data world developed by R-Cycle. Thus, R-Cycle offers a complementary approach to other circular economy initiatives.

No, for example, the recipe of Coca Cola is top secret. And although the ingredients are listed on the bottles, no one can copy the drink. Moreover, with R-Cycle, only relevant information is recorded. Process data or ingredients that have no relevant influence on the application in question are not included. In addition, the system has the latest security standards as well as different authorization levels: End users, for example, cannot view the same information as manufacturers.