Digital Product Passports for smart Digital Watermark packaging in blow molding

Together with plastic raw material supplier Braskem, plastic packaging manufacturer KautexTextron and Netherlands-based recycling specialist company Morssinkhoff Plastics, Kautex Maschinenbau has launched its second R-Cycle pilot project “Smart digital watermark packaging in Blow Molding”. The project objective is to make further contribution to the future functional circular economy by fulfilling the needs of the Digital Product Passport.

How do we improve the recyclability of packaging in extrusion blow molding?

In order to make this project cover as many application areas as possible in consumer packaging, our target products are:

- 250ml beverage bottle

- 1L cans for solid detergents

- 3L gripper bottle for household chemicals

- 20L jerrycan for chemicals and special fluids

All articles are made of PP or PE, produced in mono-layer design and manufactured with extrusion blow molding processes. The product caps and lids are also made of polyethylene or polypropylene. The Mono-layer design and the usage of the same material for packaging components improves a lot the recyclability of the packaging.

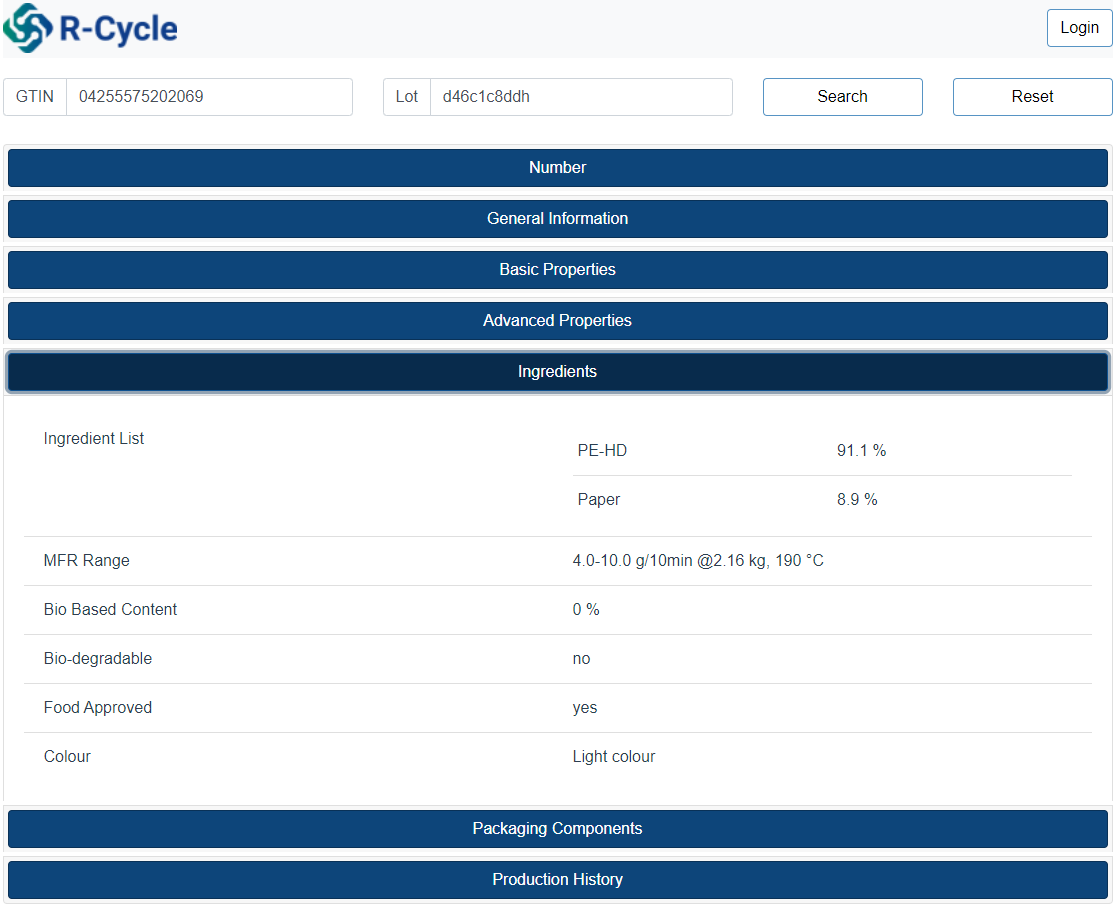

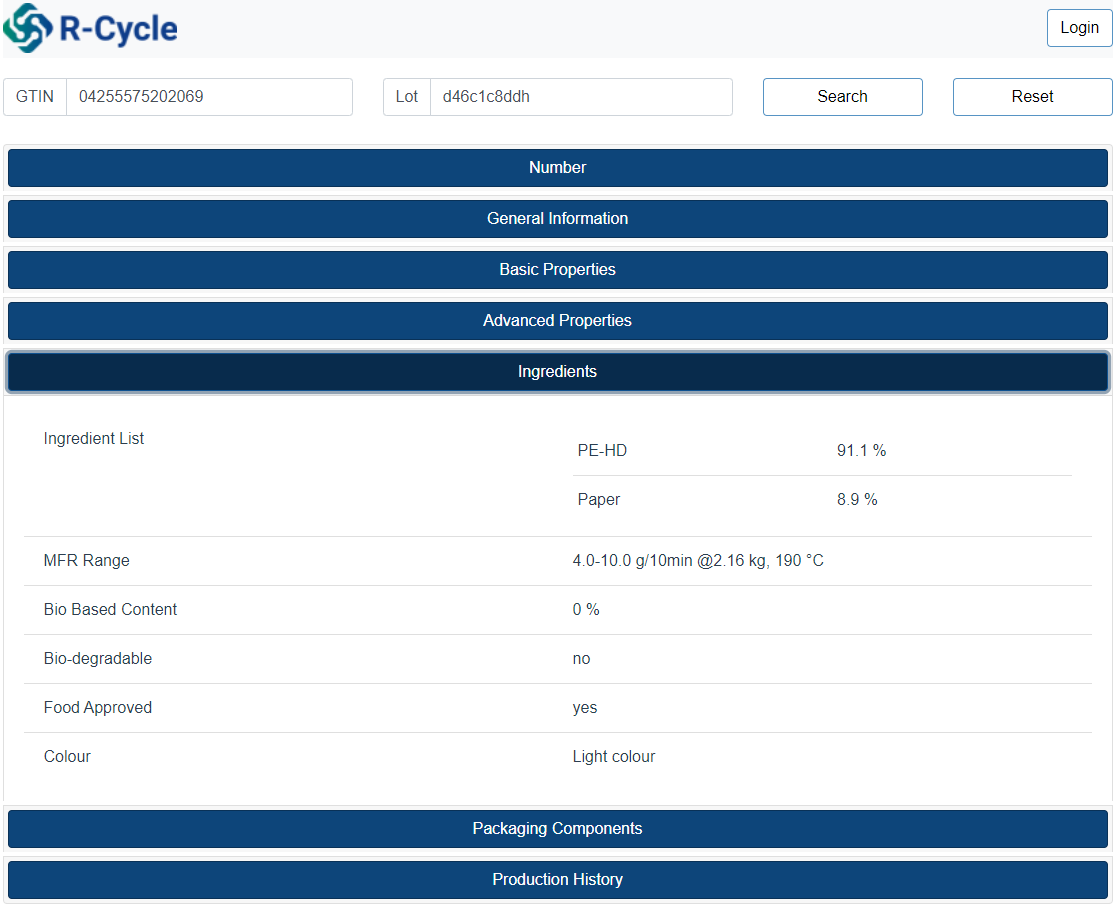

How do we store properties of plastic packaging for the Digital Product Passport?

R‑Cycle provides an open and globally applicable standard for the automated data transfer process. All recycling relevant information – the manufacturer, the types of plastic contained, the content of recycled and biobased material, and details regarding the packaging’s application in food or nonfood area – is recorded by the Kautex blow molding production platform. During the production process all data is sent and saved on the R-Cycle server using the global tracing standard GS1 EPCIS. This format fulfill the formal needs of a Digital Product Passport. A marker is applied here to identify and read that information in further converting processes and to the waste sorting process. R-Cycle is open to a range of different marking technologies for example the QR-technology or digital watermark code.

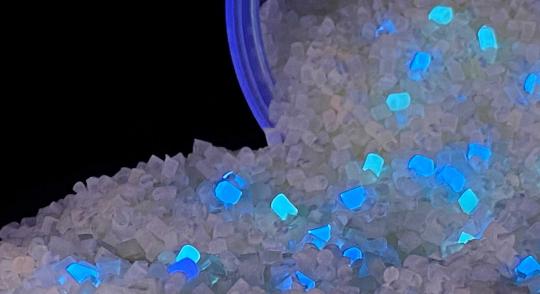

In the second step of the new pilot project, a digital product passport is generated for each article and made retrievable via digital watermarks. These marks, which are invisible to the human eye and duplicated across the entire surface of the packaging label, are the important key to link to the R-Cycle database. Thus, the digital watermarkers enable access to all relevant information, which are mentioned before. With this technology, waste sorting systems with an appropriate detection system can identify fully recyclable packaging more precisely. In the end, this provides the acquisition of high-quality materials for a truly effective recycling system and ensure highest grades of recyclate. Additionally, these codes can be read for demonstration purposes on any smartphone by each end-user by simply using the Digimarc app.

How do we enable the traceability in extrusion blow molding?

As part of the pilot project, the recycling relevant properties were collected on production platforms of the customers and partners involved. It was sent to and stored on the R-Cycle server using GS1 standards. With this real-time transmission, the data is immediately accessible along the whole value chain.

Kautex’ main development of the pilot project is the data collection system “R-Connector”, which functions as link and interface between the extrusion blow molding production and the cloud-based R-Cycle platform.

By using the “R-Connector” in Kautex production solutions, all necessary production data will be recorded, analyzed, and uploaded to R-Cycle in real time. This increases production efficiency and transparency significantly. In this way, waste sorting facilities can identify fully recyclable packaging by using standard detection technologies. Most importantly, this open and globally applicable tracing standard is the key to obtaining high-quality recyclate for true recycling in the future.

Stay tuned for further updates on progresses about the Kautex pilot project.

Find out more about Kautex Maschinenbau: www.kautex-group.com

More Success Stories from R-Cycle